Steam Cleaner Continuous Refill

$1,500.00

Title

$1,500.00

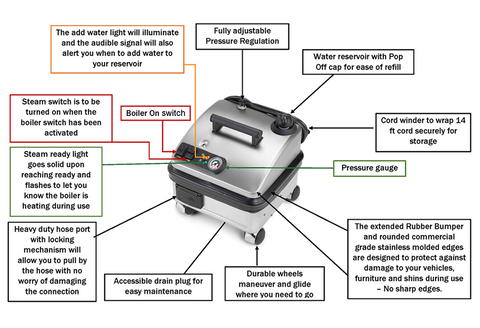

The Continuous Refill Duo Steam Cleaner is a powerful and versatile commercial grade steam cleaner, designed to get the toughest jobs done. It produces steam at 327 F with a maximum pressure of 87 PSI (6 bar), this steam cleaner delivers a high volume of steam to effectively remove pests, dirt, grime, and stains from floors, walls, countertops, mattresses, couches and more. The dual resettable high limit 180c thermal fuses offers protection like no other. It features a 1.8 capacity boiler - 2 Qt. reservoir which gives you a non-stop refill reservoir , meaning no down time to refill and reheat.

The power of the steam will ensure a perfect hygiene that is able to melt even the toughest dirt or pests without using any chemicals. All you need is water

The power of the steam will ensure a perfect hygiene that is able to melt even the toughest dirt or pests without using any chemicals. All you need is water

- WHAT TO LOVE

- HOW TO USE

- DELIVERY & RETURNS

WHAT TO LOVE

- BUILT TO LAST – Stainless Steel encases the highest quality components and a well refined design to ensure an extended life expectancy.

- POWERFUL - Encased in this package is an amazing combination of temperature, pressure with less than 5% moisture dry steam. Deep clean naturally, sanitize, kill dust mites, bedbugs etc., as well if not better than any steam vapor cleaner or on the market. Clean easily and swiftly while sanitizing 99.9% of all germs in your home or business.

- OPTIMAL PERFORMANCE - 1.8 capacity boiler - 2 Qt. reservoir...non-stop refill reservoir no down time to refill and reheat to work all day and a 9.75 ft extended length detachable Hose w/ Safety Handle and fingertip control. Dual (2) resettable high limit 180c Thermal Fuses offering protection unlike any steamers.

- FUNCTIONALITY - Made with a Stainless Steel Insulated Boiler, an audible beeper notification when reservoir needs refilling and a safety Shut off and Pressure relief valve. Features a heavy load CEME water pump for consistent flow and less stress and 4 Large Casters for easy mobility & durability

- 31 PC SET - A complete set of 31 excellent Commercial grade tools & accessories included

HOW TO USE

PLEASE READ THE MANUAL BEFORE FIRST TIME USE

1. Remove the pop off black cap from the reservoir and fill to the top with filtered water or high quality tap water. Do not use distilled unless mixed with tap water at a minimum ratio of 20% tap/80% distilled.

2. Push down both power & steam buttons that will light orange/red. The pump will begin to pump and both the yellow low water and green/amber lights will flash, the orange add water light will stop flashing, the green/amber light will continue to flash. You may need to add water more than once. The gauge will rise to approx. 6 bar and the steam heating/ready light will go solid.

3. During this time you may attach your hose and confirm it is locked in place.

4. When the gauge has stopped and the steam ready light is solid, pull the trigger on the hose and begin releasing air from the boiler. The first release will cause the gauge to drop quickly to approximately 2 bar. This has now released a large portion of air from the boiler.

Allow the gauge to rise again to the 6 bar range and the ready light is solid – pull the steam trigger and release. This time it should only drop to 3-4 Bar and repeat this action typically one more time.

You are now ready to steam, your boiler is full and will stay that way unless you empty it for maintenance. Refill anytime your refill light illuminates and the beeper notifies you. Your steam ready light will always go solid while heated and sitting idle, and will flash when you are using the machine as this indicates the boiler is heating as you are steaming.

DELIVERY & RETURNS

Delivery

Shipping time varies based on your location. All products are shipped from NY and shipping time is usually 2-10 days. If you need the item sooner, please look into expedited shipping.

Returns

Returns are accepted within 7 days for unused and unopened items only. To view our full return policy, please click here.